How Technology-Driven Megatrends Are Influencing the Manufacturing Sector and the Broader Global Economy

In this article, we explore how technology-driven megatrends including Digital Transformation, Artificial Intelligence and Tokenization are influencing the course of manufacturing and the direction of the world’s economy.

A megatrend is a profound movement or shift in a macroenvironment – reshaping the strategic conditions under which governments, companies and communities operate. Typically, megatrends evolve gradually. They can, however, also be kickstarted through sudden disruption and manifest when a tipping point is reached. Megatrends are evident through technological change, shifts in lifestyle and social choices, and through environmental priorities. They can also be driven by governmental action.

While it has been generally accepted for some time that continued, rapid advances in information technology (IT) and digital technologies will eventually lead to the creation of autonomous supply chains and economies over the next 15 to 20 years, many across the industrial sector believe that the COVID-19 pandemic may have been a tipping point in the evolution of autonomous supply chains.

As we look at the proliferation of autonomous developments as they pertain to the manufacturing world, we see that truly autonomous supply chain management remains somewhat aspirational as, at present, many planning and execution functions cannot be performed solely by AI and machine learning algorithms without human involvement. Take, for example the air cargo industry where being truly autonomous would require removal of human air traffic controllers, emergency response teams and customer service personnel. And while computers can efficiently process massive amounts of data such as thousands of simultaneous cargo bookings, there are any number of manual tasks that humans are currently capable of completing more quickly and accurately. Among these are certain equipment maintenance, software improvements and hardware upgrades. Other questions persist. Will autonomous transportation modes such as rail, trucking and shipping vessels ultimately be able to operate optimally in severe weather or adverse conditions, void of human supervision? And can automated shelf stocking and equipment in stores be made compact enough to function properly in retail locations, alongside human shoppers?

In manufacturing and other industries there are, of course, a significant number of operational and supply chain functions – such as order creation, dock door appointment management and inventory adjustment – that are already widely and well automated via artificial and other data intelligence. Ultimately, however, evolution to true, autonomous supply chain management will require the adoption and use of a shared, unified, digitalized data model by all supply chain partners that starts with acquisition and processing of raw material and carries all the way through last mile delivery and customer service.

Digital Transformation

According to information published by the International Data Corporation (IDC) in Q4 2022, worldwide digital transformation spending is forecast to reach $3.4 trillion in 2026 with a five-year CAGR of 16.3%. With information being digitized and harnessed through The Internet of Things, blockchain, cloud-based data storage, AI, and big data: digitalization will usher in never-before seen efficiencies. These efficiencies are connecting and integrating business, and therefore driving down the cost of trade, ideas, and technologies globally, while better coordinating global value chains. As time continues, we will increasingly see digitalized information provide the backbone for international integration, e-government and day-to-day business operations.

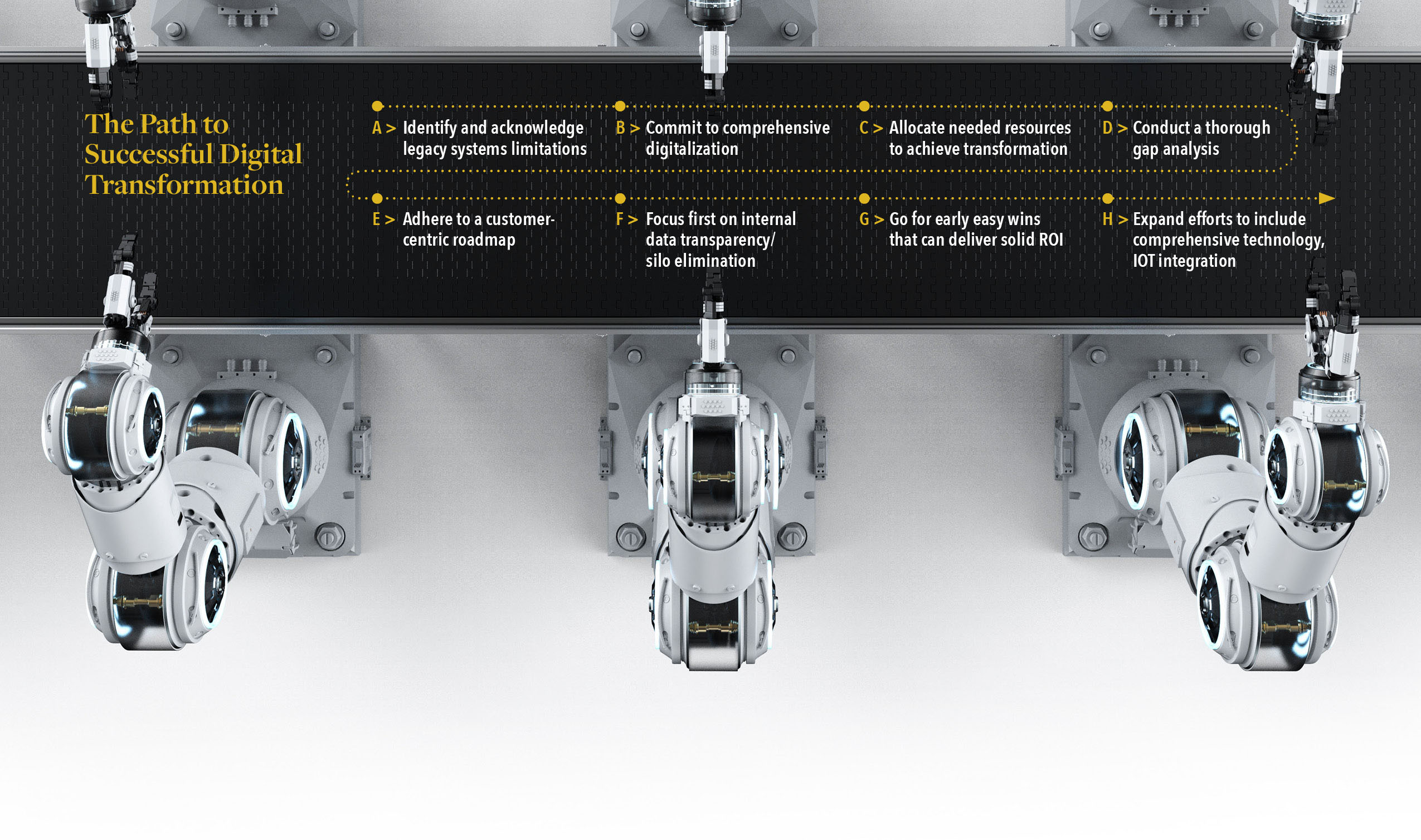

For large manufacturers, the digital transformation of operations requires a committed focus on integrating newly available AI, machine learning and other emerging technologies with the rich data that most have been collecting for quite some time on not only their own businesses, but on customers, competitors and market trends as well. While some have resisted such efforts or hesitated to invest the necessary resources toward this end, history has demonstrated that failure to stay ahead, or at least keep pace during key periods of industry transformation can have dire consequences. Blackberry, Blockbuster and Kodak, most immediately come to mind here. That said, we still find that the financial and human capital investment that many companies have previously made in what has now become outmoded legacy systems, holds them back from taking steps to advance their businesses forward.

Building upon our earlier comments, an important aspect of digital transformation is integrating workers in meaningful and effective ways rather than viewing them – or having them view themselves as simply redundant. This involves not merely getting buy in from the forklift operators whose inventory picking and warehouse transport roles are being assumed by robotic devices and autonomous vehicles. It extends to then upskilling those workers to become even more valuable members of the organization who can enjoy greater longevity and enhanced job satisfaction in new and meaningful roles.

Artificial Intelligence

It has been argued that AI will represent the biggest technological leap since the printing press. According to a recent Accenture report, AI powered technologies will increase productivity in manufacturing by a staggering 40% by 2035. AI is here and is evolving at a rapid pace, with its place in our ecology assured. It allows for intelligent decision making and appropriate responses, is self-governing, self-adjusting, decentralized and central to what has been called the “Fourth Industrial Revolution.” Coupled with big data, AI is underpinning industrial innovation and social reform.

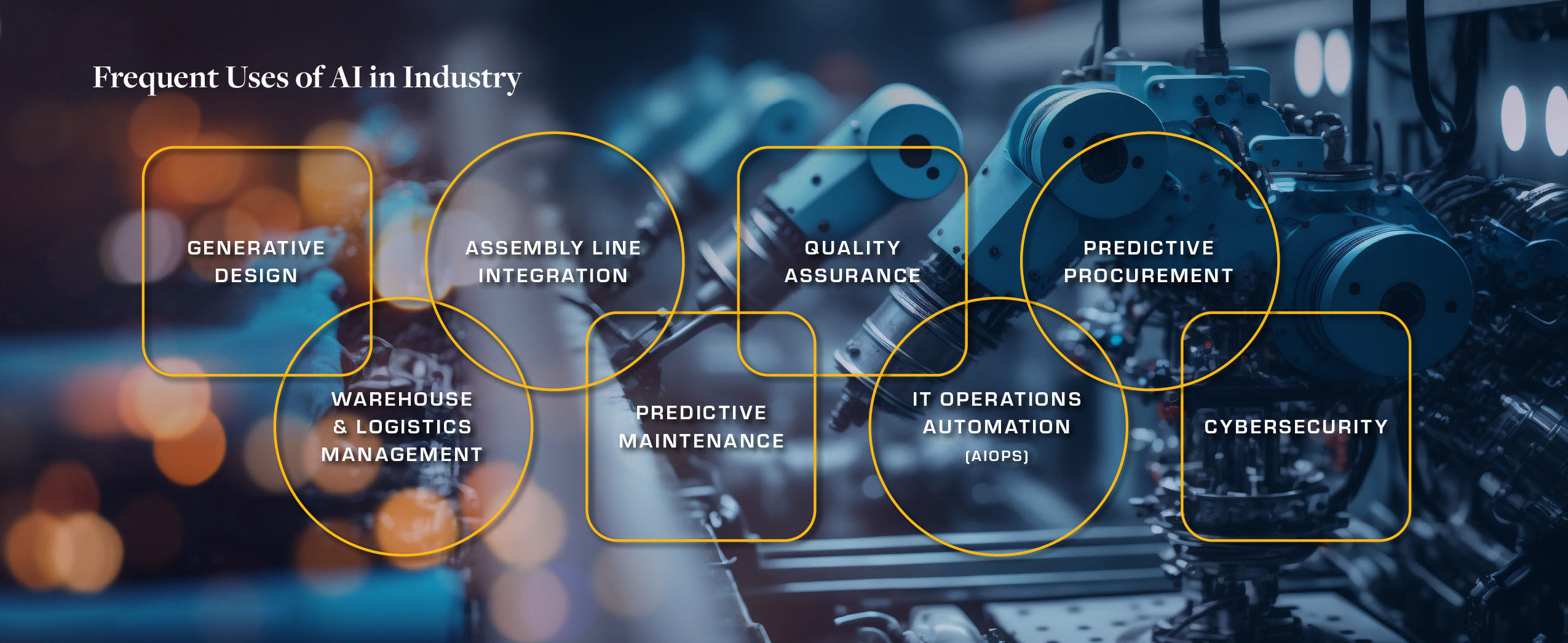

AI’s ability to transform manufacturing is already paying dividends by delivering improved productivity, minimizing defects and downtime. While this is happening mostly in larger manufacturing facilities at the present time, smaller operations are beginning to follow suit with solutions that are both affordable and highly effective.

Machine learning and neural networks capable of deep learning are being utilized to analyze data and make better informed decisions. Here too, human involvement is essential, as one of the initial steps of implementing AI involves teaching it to accomplish tasks by observing how humans accomplish them. Through this step, the AI begins the process of learning how to perform a wide range of tasks on its own with minimal future intervention. This training can be supplemented by providing additional external, crowdsourced industry data for the AI to analyze– such as best practices associated with frequently performed tasks and documented causes of efficiency or margin loss associated with various operational practices and procedures. AI also has the potential to continue the process of acquiring knowledge and learning on its own to further enhance manufacturer efficiency, quality and output.

From predictive maintenance to demand forecasting and minimizing material waste, the use of AI in manufacturing and elsewhere continues to expand. According to Grand View Research, the global artificial intelligence market size was valued at USD 136.55 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 37.3% from 2023 to 2030.

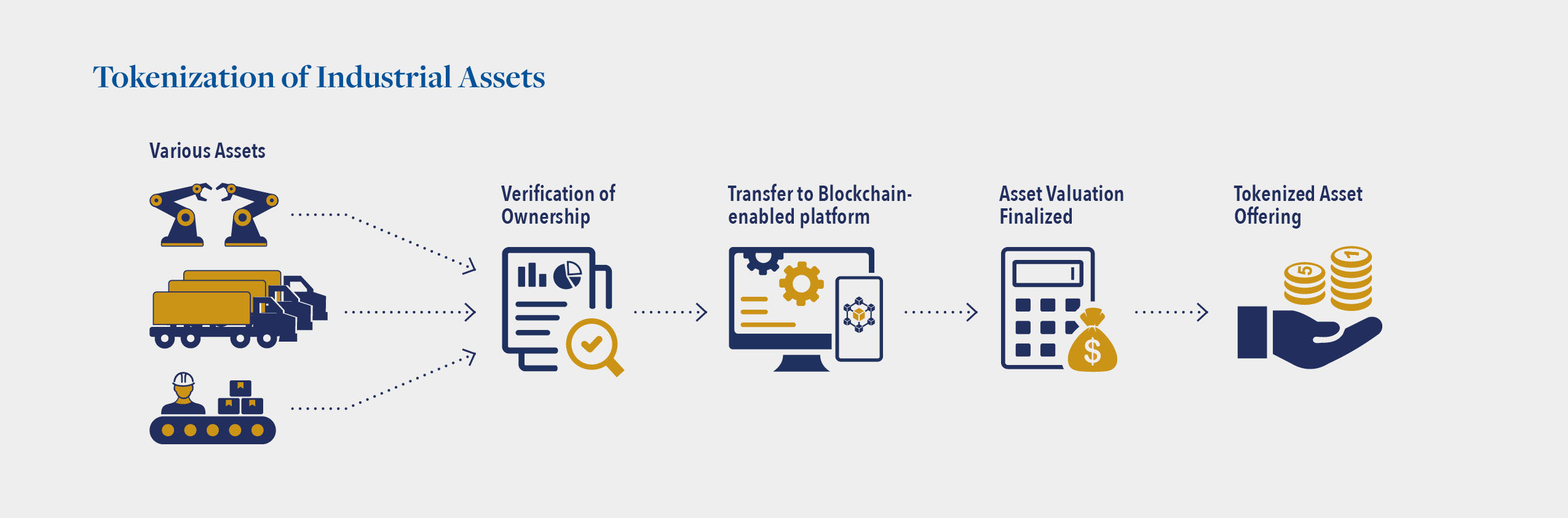

Tokenization

Tokenization involves converting ownership of physical or digital assets to blockchain-based tokens and is growing as an alternative source of investment and expansion. Some examples of assets that can be tokenized include real estate, industrial equipment, patented technologies and copyrighted images/content, currency and gold. When a business wants to buy a commercial premises or major plant and equipment, but the outlay is unaffordable… tokenization can enable the business to buy a piece of the property with as much money as they can afford. This creates a new option for small to medium-sized businesses worldwide, of which there are approximately 400 million at present, underpinning 90% of the global economy.

With an estimated 50% of Small and Midsize Enterprises (SMEs) currently facing financial headwinds- such as paying operating expenses and investment into future business development – tokenization represents an opportunity to move away from traditional financial instruments into a digital financial device that can make investment and expansion a greater possibility. It should also be pointed out here that large businesses with solid liquidity are also increasingly utilizing tokenization as a means of purchasing majority or full interests in industrial and other assets.

Tokenization authenticity and credibility, it is important to point out, is underpinned by blockchain technology– in which a decentralized, distributed, public digital ledger is used to record transactions across many computers so that a record cannot be altered retroactively without the alteration of all subsequent blocks and the consensus of the network.

A wide range of flexible usage and billing models are a key trend of digitization and are enabled through tokenization. This is allowing companies to pay for the use of capital goods and equipment (such as assembly line robotics and autonomous warehouse or port vehicles), rather than buying them outright, via use-based and subscription models with billing controlled via accurate usage data collected by Internet of Things (IoT) sensors connected to the assets themselves.

Some of these manufacturers and distributors have even implemented fully automated asset lifecycle management systems. Driving more than just automated billing, payment, and accounting functions, the data streams they generate can be used to assess risk, dictate cash flow calculate residual value and streamline refinancing for each associated asset.

Refinancing via tokenization is also evolving as an option to traditional securitization, with tokens on the blockchain representing shares in the company and an associated claim to a portion of cash flow derived from the underlying assets. These tokenized shares can be transferred between parties without fiduciary intermediaries but with the confidence of the blockchain’s digital ledger/”paper trail.” The use of smart contracts can be utilized to facilitate associated share-/token-holder distributions. That said, before the full potential of tokenization can be realized as a financial/investment vehicle in regions around the world, certain infrastructure and regulatory hurdles will, no doubt, need to be met. For now, however, we will leave that topic for a future article.

Concluding Thoughts

The technology megatrends summarized here are already in use and are set to evolve and widely penetrate the manufacturing sector over the course of the next decade. A key challenge for those who wisely commit sooner than later to harness the full potential of these technologies on their march to join in the “Fourth Industrial Revolution” will be not merely integrating them into their businesses and supply chains, but effectively engaging their own employees as part of the transformation and effectively managing upskilling efforts to ensure success.

We are currently actively engaged with multiple organizations and encourage those across the supply chain and lenders/creditors with manufacturing or related portfolio exposure to reach out to our team for a discussion about their readiness relative to the many topics discussed in this article.

Hilco Global APAC – a Hilco Global Company – helps businesses understand the value of their assets and navigate local and global markets to monetize and maximise return. Our ability to act as not only an agent but as an advisor, investor and/or principal in any transaction differentiates us, as does our expertise in the delivery of valuation, realization and capital solutions. This comprehensive range of offerings enables our clients to better navigate through periods of significant business change.

As a diversified financial services company Hilco Global delivers unsurpassed asse knowledge and expertise to help businesses maximize asset value and financial returns at critical inflection points throughout their lifespan.

Serving as a modern-day merchant bank, Hilco Global delivers highly customized Asset Smarter B2B Valuation, Monetization, Advisory and Capital solutions, managed bymore than 800 executivesacross 22 expert operating companies worldwide.