The Shifting Tide of Plastics Value Chain Sustainability

In this article, we take a look at the momentum underway to shift the global plastics sustainability paradigm and explore the potential impact of those efforts on both the planet and businesses along the plastics value chain.

In January of this year, an alliance of global companies from the plastics and consumer goods value chain launched a new organization to advance solutions designed specifically to eliminate plastic waste in the environment, particularly in the oceans.

The “Alliance to End Plastic Waste” (AEPW), founded by nearly thirty member companies, stated its intention to invest $1.5 billion over the next five years to help end plastic waste in the environment. The Alliance is committed to developing and scaling solutions to minimize and manage plastic waste and promote practices for used plastics by working to better enable a circular economy. Its membership represents global companies located throughout North and South America, Europe, Asia, Southeast Asia, Africa, and the Middle East.

The Scope of the Issue

It is estimated that approximately 8 million metric tons of plastic are deposited in the world’s oceans every year. Many plastic products are designed for a single-use after which they are discarded. Water bottles are a perfect example, as are straws, which we have seen become the “poster child” of sorts for the importance of change in the industry as momentum builds to replace the plastic variety with biodegradable paper alternatives on a widespread basis. Other plastic products most widely found in the environment include convenience food and beverage packaging/wrappers, utensils, cups and plates.

From these single use examples to single-use items such as children’s toys, light-duty appliances, household storage containers and countless others… when not properly disposed of, these often end up in our oceans where they cause further damage to an already fragile ecosystem.

In addition to the plethora of floating and sunken plastic remnants which have become all too common a sight these days, tiny micro-plastic pollutants also populate our waters and shores. These range from fragments of soap, hair care and other consumer products to portions of clothing and commercial fishing nets. To make matters worse, these are typically infused with dangerous chemicals such as dyes and pesticides.

At the core of the issue is not merely the manufacture and widespread use of plastics in today’s society but, importantly, the lack of expertise and education on how best to dispose of them in such a manner that prevents pollution of both land and sea. With this in mind, advocates for change face a challenge in terms of how best to turn awareness of, and openness to, the issue of plastics pollution into actual change that can transform how we think about and use plastic products.

Momentum is Building

The shift in thinking that is now occurring is centered around the idea of a “Circular Economy” where we plan for and execute a process that ultimately views plastics as a resource to be used repeatedly over time.

As this takes shape, every industry that touches plastic during its lifecycle will likely play a role in helping to eliminate plastic waste in the years ahead. The solution rests with 1) Chemical companies, which can develop polymers that allow those who process plastics to consume less material yet still maintain the quality of their products; 2) Processors who can then use less resin to produce quality products with the same properties; 3) Consumer goods companies which, in turn, can design packaging that is more easily recyclable; 4) Waste companies which can develop more comprehensive trash collection practices and consumer education efforts to help prevent plastic from entering the environment and; 5) The many tens of thousands of general businesses, cities and municipalities around the world that can work to implement improved waste segregation efforts that ultimately enable collected plastics to be pure enough for streamlined recycling and reuse by the chemical industry. The entire value chain will and must be engaged to make this a success.

In the automotive industry, for example, the development of lighter weight plastics and composites used in the passenger compartment, body trim and semi-structural components have been increasingly contributing to vehicle efficiency and extended life spans. In addition to reducing fuel consumption and maximizing electric vehicle battery life, thanks to recent advances, the thermoplastic attributes of many parts now enable them to be melted and re-formed into new components rather than being discarded as waste.

From places like Germany and Switzerland to Los Angeles and Portland, innovation, education and activation efforts are intensifying in regard to the consumption and disposal of these plastics. Reusable cups, dishware, cutlery, to-go containers and systems for their collection, sanitation and reuse are being developed, tested and deployed. This confluence of factors serves to validate the AEPW’s relevance and punctuates why it is so critical for those stakeholders (and investors) across the “plastics value chain.”

A Promising Trajectory

Eight months into its evolution, the not-for-profit AEPW Alliance has grown by 25% to 40 member companies that make, use, sell, process, collect, and recycle plastics. This includes chemical and plastic manufacturers, consumer goods companies, retailers, converters, and waste management companies. Among the ranks are the likes of Exxon Mobil, Dow, Chevron Phillips, BASF, P&G and a host of other titans.

Efforts are well underway already across the Alliance’s four key areas of focus:

Infrastructure development, Innovation, Education & Engagement, and Clean- Up. Along with the World Business Council for Sustainable Development as a founding strategic partner, the Alliance is beginning to work with cities to design integrated waste management systems in large urban areas where infrastructure is lacking, especially those along rivers which transport vast amounts of unmanaged plastic waste from land to the ocean. This work will include engaging local governments and stakeholders, and is intended to generate economically sustainable and replicable models that can be applied across multiple cities and regions. The Alliance’s plan is to pursue partnerships with cities located in high plastic leakage areas and will also be looking to collaborate with other organizations around the world.

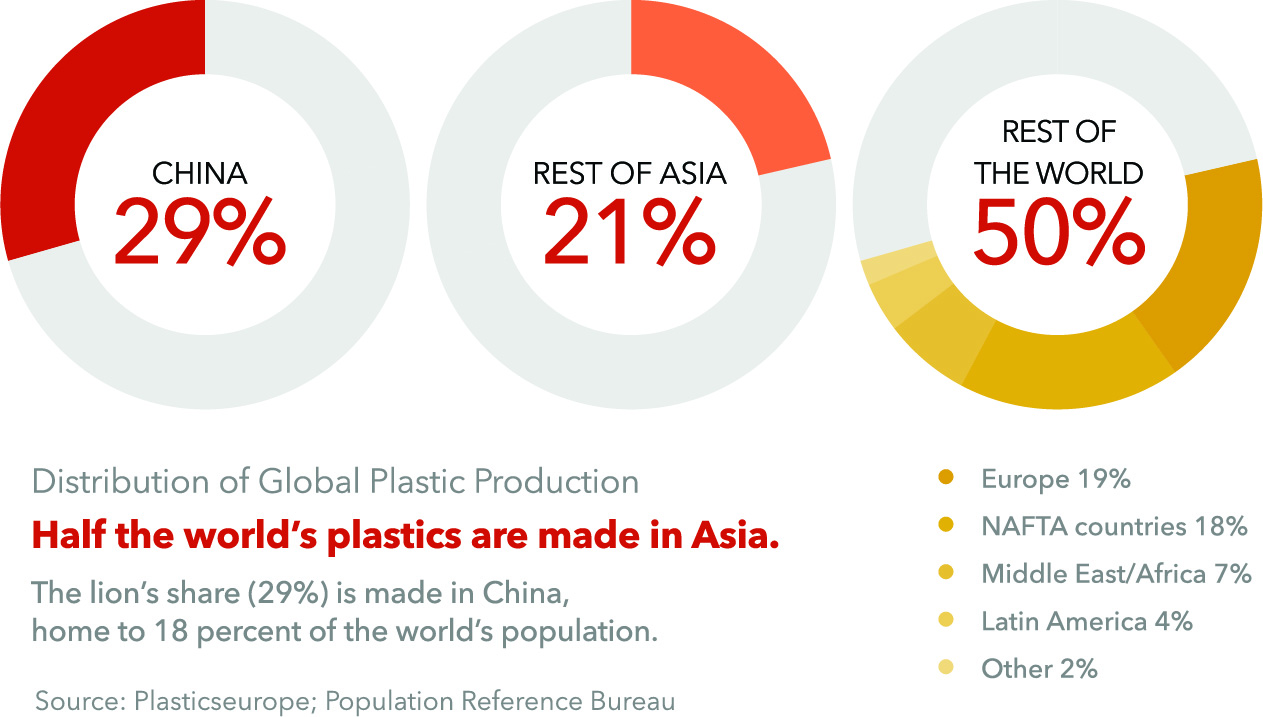

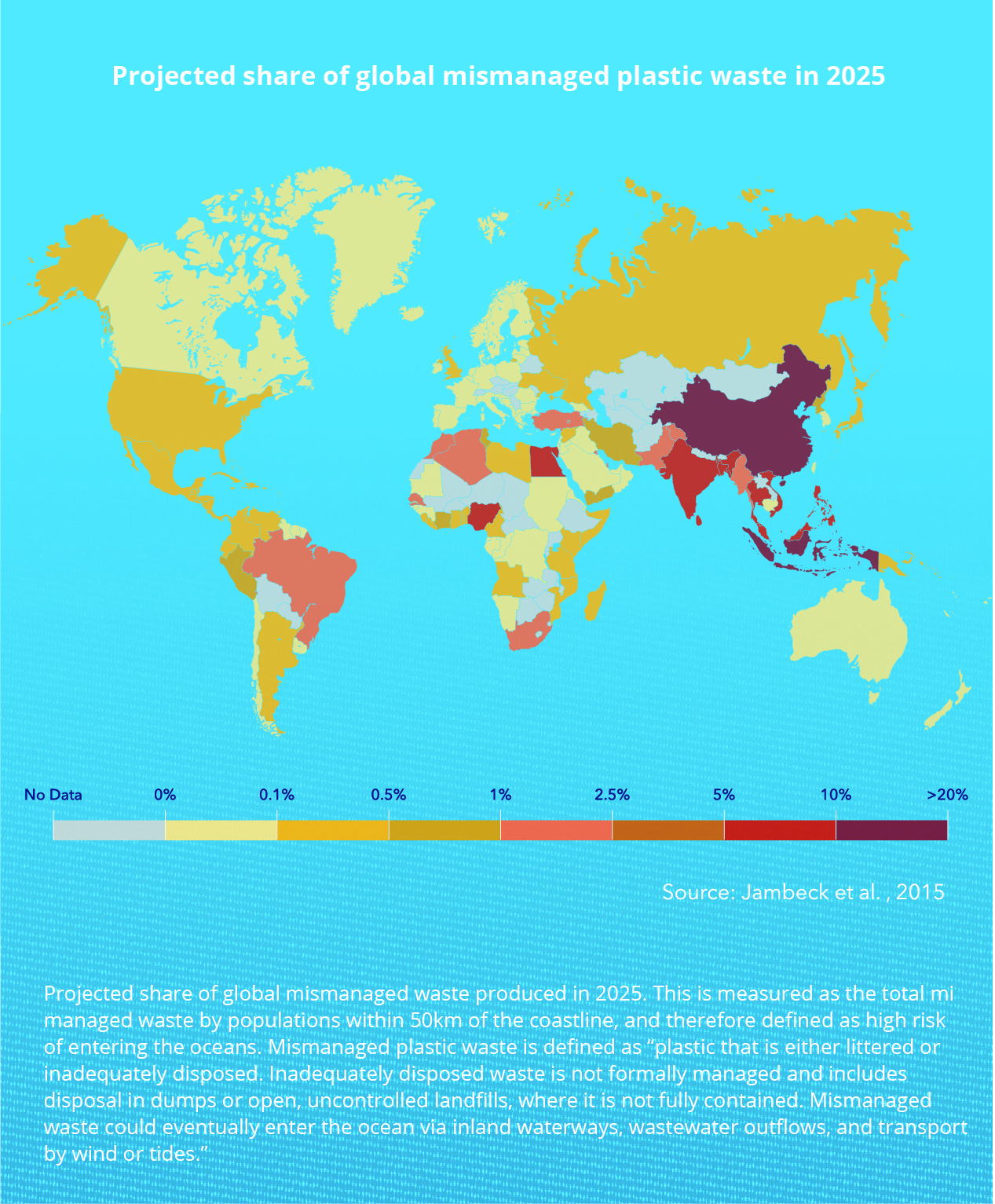

Separately, across the globe, countries and communities are mobilizing to make an impact. When it rains or floods along the banks of rivers in Indonesia, for example, local residents gather together to clean the plastic and other waste that floats across the top of the water like a carpet. About half of the more than 3 million tons of plastic waste that Indonesia produces annually ends up in the ocean, making it the world’s second-largest contributor to plastic ocean pollution, behind China. In fact, just 10 of the world’s rivers account for some 90% of the more than 8 million tons of plastic waste that is washed into the oceans annually. Eight of these are located in Asia and the other two in Africa. Focusing waste management efforts on just these 10 rivers could have a significant environmental impact.

127 countries have effectively reduced the use of plastic bags through policy efforts and measures. About 27 nations also have active legislation to either ban or significantly restrict single-use plastics, namely straws and dishware.

— Source: U.N. Environment Programme and the World Resources Institute

In China, where officials are struggling to control river pollution without inhibiting economic growth, environmental issues are under the microscope. Part of the country’s solution has been to appoint local political leaders as watchdog “River Chiefs,” require provinces to meet their water quality targets, and raise penalties for polluters. For example, provinces were previously required only to reduce the quantity of pollutants entering bodies of water. They are now also required to ensure that water quality meets targets, and they can be barred from building new factories if those targets are not met.

And in the oceans, scientists are beginning to place devices for measuring plastic pollution on commercial vessels, allowing them to determine how the material moves and accumulates. The information collected will likely inform a long-term, comprehensive strategy for clean-up.

The European Union, too, is looking to test new high-tech solutions for cleaning up plastic pollution. One approach is said to involve coating plastics with a substance which, when activated by light, would degrade common micro-plastic pollution. Another would use robotic arms equipped with scanners to recognize and remove plastics from rivers. One forward looking group even envisions synthetic gas-powered garbage collection barges, fueled by conversion of the very plastic they remove from rivers.

Overcoming Challenges

Needless to say, these disparate efforts are part of a collective mindset and commitment to affect change before achieving such change becomes insurmountable. Yet, remarkably, here at home and elsewhere around the world many people still don’t realize the importance of being diligent about recycling or the reason why recycling plastic requires meticulously separating it into its various chemical types. “Plastic” is really a blanket term for several types of materials that are in fact used to manufacture items such as soda bottles, trash bags, cling wrap, shopping bags, yogurt containers, fishing nets, foam insulation and even household appliances. And recycling each of these types, including PETE/PET (Polyethylene Terephthalate), HDPE (High Density Polyethylene), PVC, PVC/V (Vinyl), LDPE (Low Density Polyethylene), PP (Polypropylene), PS (Polystyrene) and other miscellaneous plastic resins, requires a distinctly different chemical process.

This is why effective sorting of materials is so critical to the future success of recycling efforts around the world. While many community household recycling programs specify that residents sort their plastics, others allow them to place recyclables of all types into one container and then use third party resources for sorting after collection.

Additionally, the process of recycling in general, requires the use of extreme heat to break down the polymers which provide these plastics with their structure. As a result, after being recycled in this manner once or twice, this “downcycled” plastic can only be reformed into harder, more dense materials that ultimately end up in landfills.

Given these challenges, it is hard to imagine the scope and complexity associated with effectively recycling the plastic collected from river and ocean clean-up efforts. With so many types of plastics in such varying states of decay from lengthy exposure to both the sunlight and powerful currents, the effort is a massive undertaking. In addition to involving the collection of tiny “microplastics” suspended almost invisibly below the water’s surface, much of the other visible plastics are now intertwined with a variety of other organic and man-made materials, making the process both painstaking and costly.

Among other partnerships, the Alliance is providing funding to support two initial project partners: The Incubator Network by Circulate Capital and SecondMuse, which are working to develop and promote technologies, business models and entrepreneurs that prevent ocean plastic waste and improve waste management and recycling. The intent is to create a pipeline of projects for investment, with an initial focus on South and Southeast Asia.

Focusing on the prevention of mismanaged plastic waste in these regions is a sound first step because countries located in South and Southeast Asia often lack adequate waste infrastructure and therefore contribute disproportionately to ocean plastic pollution. Efforts here can become a model for addressing other leading sources of plastic marine and other debris the world over.

Lender Ramifications

As more partnerships are formed among NGOs, industry, and governments around the world, the result is likely to bring innovative solutions to this challenge of sustainability, which will be felt in the U.S. and elsewhere across the globe.

In addition to widespread clean-up of rivers and oceans, the outcome that we expect to see evolve over time is that plastics themselves, plastic-only products and even plastics that are integrated with other materials and components, will begin to be engineered from the start with greater qualities of recyclability.

If your organization is currently lending to companies that either make, use, sell, process, collect, or recycle plastics, it is important to recognize that changes are occurring that are ultimately going to begin to impact these businesses; particularly those without the financial or other resources required to maintain pace and competitiveness. While the exact nature and timeframe of those changes remain to be seen, Hilco Valuation Services continues to advise our clients and others invested across the plastics value chain to closely monitor and frequently review their portfolio businesses to ensure an up-to-date grasp of how inventories, turnovers, types and disposition requirements are being impacted.

Hilco Valuation Services is the leader in valuation for the plastics and chemicals industries, with more than 300 appraisals delivered on asset values ranging from $10 million to over $1 billion.