Q4 ’22 Sustainability Update: Efforts Proceeding Along the Right Path

Our quarterly sustainability updates include insights and data from the Hilco Valuation Services team, pertaining to the plastics and chemicals Industries, and are applicable to a host of businesses operating in various sectors and other industries around the world.

ARE PLASTICS AND CHEMICALS THE PROBLEM OR THE SOLUTION?

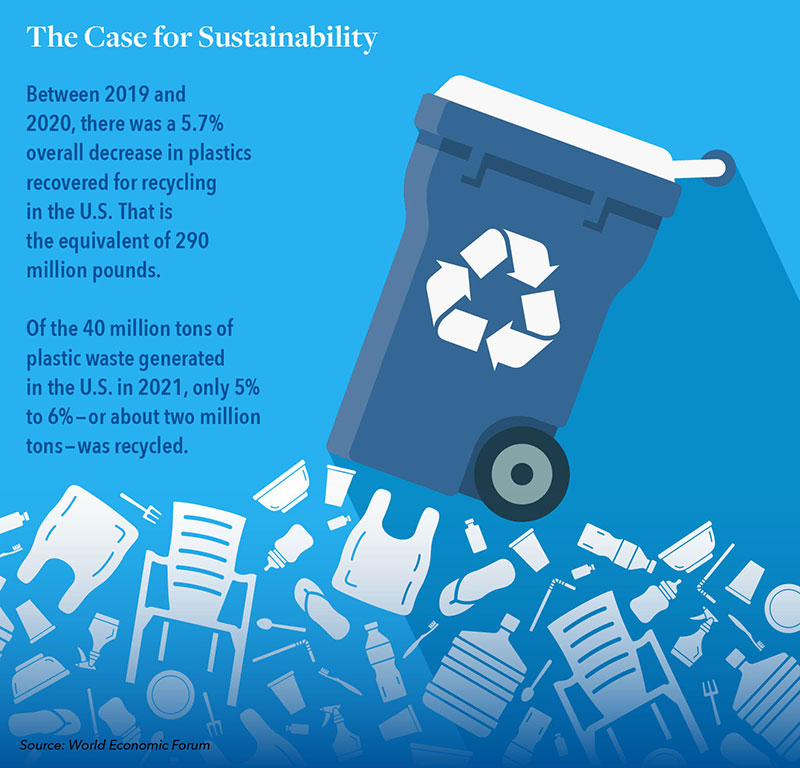

The proliferation of plastic into the daily lives of people around the world over the past many decades, and the slow nature of how it degrades over time, has resulted in plastics filling our landfills and polluting our waters. According to the Plastic Pollution Coalition, this has been exacerbated by the fact that approximately 40% of plastic items in use today, such as plastic shopping bags, are intended for single use purposes. As a result, plastic particles are showing up with increasing frequency in our food stream. The good news is that institutions around the world, such as Northwestern University’s McCormick School of Engineering, are working on innovative solutions including new polymer designs and upcycling processes.

The question of how best to tackle the challenge of recycling complex materials found in products such as tires and mattresses is just one of the issues that remains to be solved and, as a result, millions of pounds of these and other such items continue to build up in trash in dumps and landfills worldwide.

The majority of plastics are created via extraction of raw materials such as crude oil, natural gas and coal.

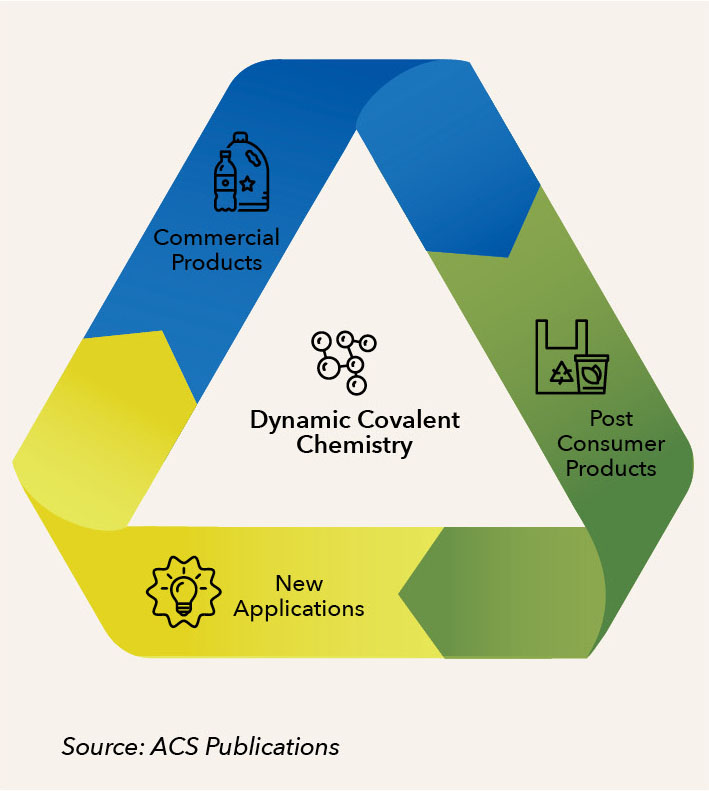

These undergo a refining process which transforms them into ethane and propane. When treated with heat, these are transformed to ethylene and propylene, which in various combinations create different types of polymers. Exploring methodologies for altering the chemistry behind some of the complex materials found in the products creating landfill issues can makes these items recyclable in the future. The Torkelson research group, for example, has found several ways to create a new material type called “dynamic covalent cross-links,” which would be recyclable. One such method activates the covalent cross-links found within polyurethane foams to break and reform rapidly during the process of recycling, enabling polymers to be melted and then reshaped into new types of products.

This type of upcycling is able to break polymers down to their fundamental components. At Northwestern, the team led by Monica Olvera de la Cruz, Lawyer Taylor Professor of Materials Science and Engineering and Chemistry, has provided the basis for a technique to enhance the effects of an enzyme that breaks down the plastic used to make soda bottles and inexpensive clothing — commercially termed PET — into its fundamental parts.

With more and more top universities and large corporate R&D departments actively investing in developing solutions, and governments around the world more actively enacting and enforcing sustainability policies, plastics may well be the solution — not the problem — in the not-too-distant future.

While there is a very long way to go, plastics pollution has the potential to be effectively addressed once plastics, themselves, become a sustainable part of the materials mix. Governmental policies, consumer education, feedstock availability, market acceptance of new technologies and materials, and the speed of the accelerated investment we noted earlier, will all be factors in how long it takes us to reach a truly sustainable future.

At Hilco, I have personally come across some great examples of sustainability. Companies we have worked with including Delta Plastics and Kraton Polymers, among others, are making great strides and should be applauded for their efforts. Delta Plastics has a closed-loop production and recycling process and manufactures Polytube, a plastic tube utilized for irrigation in a variety of farming applications including rice farming. The company collects and recycles the polytube and other plastics to produce recycled resin that is primarily consumed to produce items like polytube, bags, and liners. Kraton Polymers utilizes a pine waste product from a paper manufacturing process as their primary raw material for their pine products business. Its polymer business produces highly recyclable product solutions, as well as CirKular+™ products which utilize an innovative upcycling manufacturing process.

Still, however, not all companies and efforts are proving successful. Multiple recycled PET manufacturers have been forced to sell or are now closed as a result of tight spreads between the cost of raw materials and the market value of recycled PET. The resulting thin margins amplified already difficult and costly manufacturing challenges such as inconsistent feedstock quality and supply, significant amount of manual labor, especially around removal of contaminates, and finish product inconsistency.

There are clearly multiple lenses through which to view the level of progress that has been achieved in meeting plastic recycling sustainability goals, and Greenpeace pulled no punches in the recently issued 2022 update of its Comprehensive Survey on the topic, stating: “After three decades and billions of dollars of taxpayer spending, the excuse offered by the American Chemistry Council (ACC) that plastic recycling is still “in its infancy” can now be seen for the delaying tactic that it is.”

SO WHAT IS THE BOTTOM LINE RIGHT NOW?

While challenges clearly persist today and will continue for some time to come, the diligence and valuations we are performing in conjunction with our work on behalf of chemicals and plastics manufacturers — as well as for those seeking to make investments and acquisitions in the space — strongly suggest that efforts are proceeding along the right path, albeit a long and unpredictable one. The hope, of course, is that the ultimate payoff will be a much broader level of sustainability success that benefits both the planet and all of us, as its current inhabitants.

If your business, or businesses in your portfolio, are participants in the chemicals and/or plastics industry, or anywhere along its supply chain, I encourage you to reach out to our team to discuss any questions or concerns you or your team may have. We are actively involved in the space and are having conversations every week that can likely bring some added clarity to your situation. We are here to help.

Hilco Valuation Services is the leader in valuation for the chemical industry with hundreds of highly accurate appraisals delivered on asset values ranging from $10 million to over $1 billion. Hilco Valuation frequently works hand-in-hand with other Hilco operating companies including Hilco Performance Solutions (HPS) to provide cross-functional Manufacturing Operations, Supply Chain, People, Mergers & Acquisitions, and Commercial expertise to the chemical and other industries. By teaming highly regarded industry veterans with advisory experts, we are uniquely positioned to deliver optimal solutions that assist businesses to achieve favorable outcomes under a wide range of market conditions and circumstances.