Strategic Sourcing for Middle Market Manufacturers

In this article we provide an overview of the practice of strategic sourcing and discuss best practices for its implementation within purchasing organizations.

Strategic sourcing can be traced back to the mid-20th century when the concept of procurement began to evolve from a transactional process to a more strategic function. Prior to this, procurement was primarily focused on buying goods and services at the lowest possible cost.

As businesses began to grow and competition increased, procurement became a more complex function that required a more strategic approach. By the 1980s, strategic sourcing – the process of identifying the most cost-effective suppliers for goods and services, taking into account a variety of factors such as quality, reliability, and innovation – began to emerge as a way to optimize procurement processes and drive cost savings.

In the 1990s, strategic sourcing gained widespread adoption as a result of globalization, which led to increased competition and the need for companies to source goods and services from around the world. Simultaneous advances in technology and the rise of the internet contributed to the traction by making it easier for companies to access information about suppliers and to manage their procurement processes more efficiently.

By the 2000’s, strategic sourcing had become common practice for large companies, although it remained too complex an undertaking for most, smaller middle market companies to implement. Large companies had ERP systems that provided the data required and trained finance and procurement teams.

Today, strategic sourcing is a core component of supply chain management and is increasingly being used by companies of all sizes to reduce costs, improve supplier relationships, and enhance their overall competitiveness.

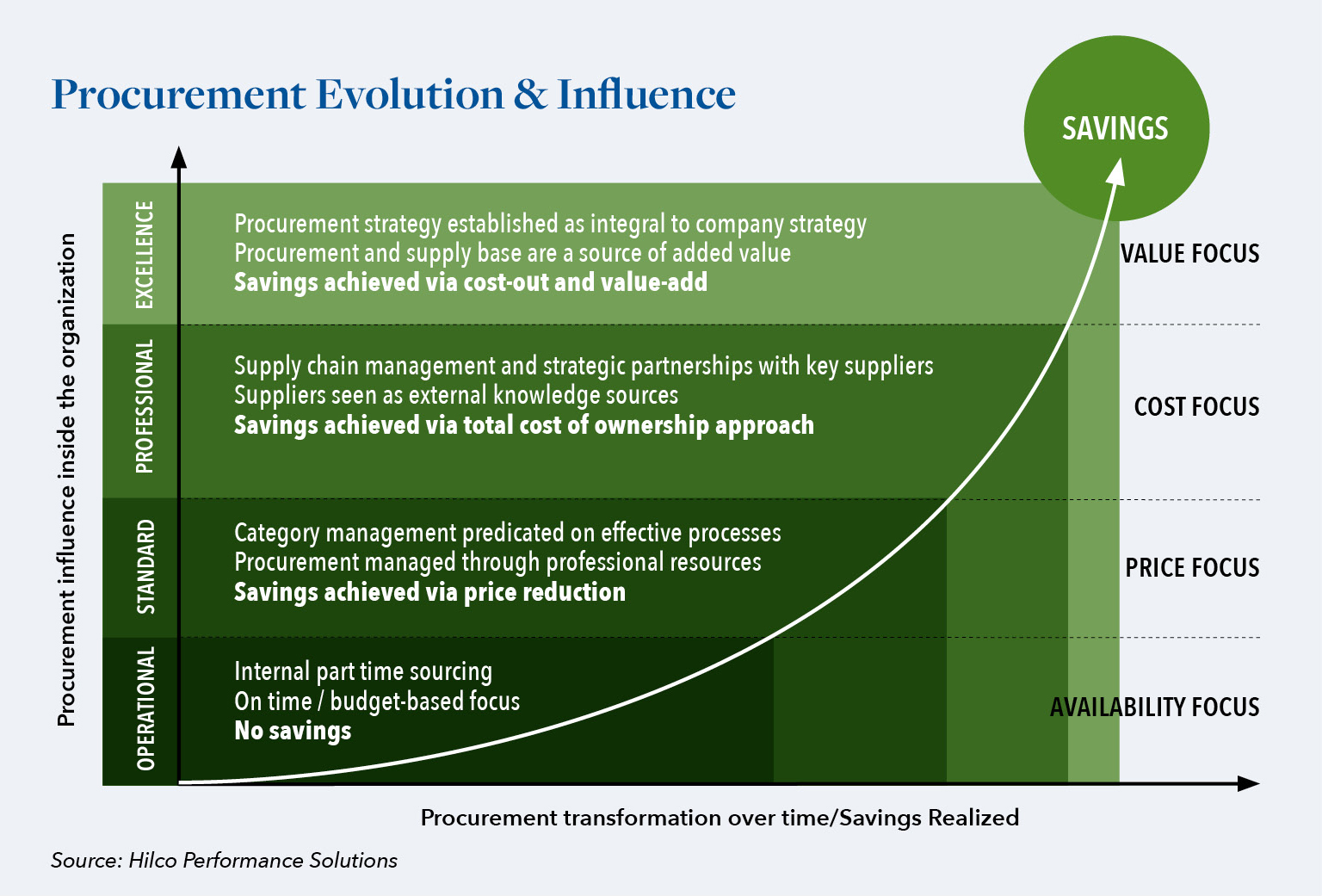

The Procurement Maturity Model

Before we dive further into strategic sourcing, it is important to review a procurement maturity model to see the different levels of procurement sophistication.

The model is a framework that helps organizations evaluate their procurement function and identify opportunities for improvement and typically consists of five steps:

Level 1: Reactive: At this stage, the procurement function is reactive and focused on transactional activities such as processing purchase orders and managing supplier relationships. The procurement function is not yet seen as a strategic partner to the business.

Level 2: Developing: At this stage, the procurement function is beginning to develop more strategic capabilities. The focus is on cost savings, and procurement is seen as a tactical function that can contribute to the bottom line.

Level 3: Performing: At this stage, the procurement function is performing well and has become a strategic partner to the business. The focus is on value creation, and procurement is seen as a driver of innovation and competitive advantage. These companies have good analytical capabilities and are starting to work cross functionally, especially with product engineering and manufacturing.

Level 4: Leading: At this stage, the procurement function is a leader in the organization and is driving change across the business. The focus is on continuous improvement, and procurement is seen as a source of expertise and knowledge that can help the business achieve its goals.

Level 5: Visionary: At this stage, the procurement function is a visionary and is shaping the future of the business. The focus is on driving innovation and transformation, and procurement is seen as a strategic partner that can help the business stay ahead of the competition.

It is important to note that each stage of the procurement maturity model is characterized by different levels of capability, performance, and value contribution. By using the model, organizations can assess their current state, identify opportunities for improvement, and develop a roadmap for moving to the next level of maturity. We should also note that Level 5 is not necessarily the goal for most organizations. Many organizations find their sweet spot somewhere between Levels 3 & 4.

We want the procurement organization to fit within the overall supply chain capabilities. Companies with domestic customers and vendors, and one or two manufacturing facilities do not need the same capabilities as global companies with dozens of manufacturing facilities. It sounds obvious, but we find that sometime companies tend to focus on developing organizational skills they don’t necessarily need to thrive in their space.

Additionally, strategic sourcing is a capability that is rare in Level 3 (Performing) procurement teams and is foundational for organizations looking to become leaders in the procurement function (Level 4). Other capabilities found in Leading procurement organizations include: Total cost of ownership (TCO), Supplier relationship management (SRM), Category management and strategic outsourcing.

Strategic Sourcing Overview

Strategic Sourcing is a systematic process that involves undertaking the following key steps to identify the best suppliers for a company’s needs:

- Needs Assessment: The first step in strategic sourcing is to understand the company’s needs and requirements for goods and services. This includes identifying the quantity, quality, and specifications required for each item.

- Market Research: The next step is to research the market to identify potential suppliers that meet the company’s needs. This involves analyzing supplier capabilities, pricing, and other factors such as location, reputation, and sustainability practices.

- Request for Proposal (RFP): The company then issues an RFP to the selected suppliers, outlining the specific requirements and criteria for the goods or services. The RFP should include information on the company’s needs, timelines, evaluation criteria, and other relevant details.

- Supplier Selection: Once the RFPs are received, the company evaluates the proposals against the set criteria and selects the suppliers that best meet its needs. This includes considering factors such as price, quality, delivery times, and supplier capabilities.

- Negotiation and Contracting: The company then negotiates with the selected suppliers to finalize the terms of the agreement. This includes pricing, delivery schedules, quality standards, and other relevant terms and conditions.

- Performance Management: After the contract is signed, the company monitors supplier performance to ensure that they meet the agreed-upon terms and standards. This includes ongoing supplier evaluation and performance metrics to ensure that the company is getting the best value from its suppliers.

Following these steps, and utilizing a systematic and data-driven approach to ensure that the company selects the best suppliers for its needs, aids companies in optimizing their procurement, reducing costs, and improving supplier relationships. We have repeatedly seen projects executed in this manner provide significant value to our clients and believe they should be incorporated into any value creation plan.

Benefits Associated with Strategic Sourcing

Strategic sourcing offers several benefits (some of which we have already touched on briefly in this article) to companies that adopt this highly effective approach to procurement:

- Cost savings: One of the primary benefits of strategic sourcing is cost savings. By carefully analyzing supplier capabilities and negotiating favorable terms and pricing, companies can significantly reduce their procurement costs.

- Improved Supplier Relationships: Strategic sourcing involves working closely with suppliers to identify the best solutions for a company’s needs. This can help build strong, long-term relationships with suppliers, which can lead to improved service, better pricing, and increased innovation.

- Increased Efficiency: Strategic sourcing can help companies streamline their procurement processes, which can lead to increased efficiency and productivity. This includes using technology and automation to reduce administrative tasks and improve decision-making.

- Enhanced Quality: By carefully selecting suppliers based on their capabilities and quality standards, companies can improve the quality of the goods and services they receive. This can help reduce defects, rework, and other quality-related issues, which can improve overall operational efficiency.

- Better Risk Management: Strategic sourcing involves assessing supplier risks and developing strategies to mitigate these risks. This can help companies reduce their exposure to supply chain disruptions, such as natural disasters, political instability, and other unforeseen events.

The most effective strategic sourcing efforts involve not only a systematic, but a data-driven approach to ensure the selection of the best suppliers for its needs. This is especially important for platform companies and other businesses seeking to grow via M&A, because the analytical capabilities developed during the strategic sourcing process are foundational to synergy capture for future acquisitions.

Implementing Strategic Sourcing

At Hilco Performance Solutions, implementation of strategic sourcing focuses on partnering our knowledge of process and data with our clients’ domain expertise. This approach we follow, which is outlined below has consistently resulted in meaningful reductions in the cost of goods sold which, in turn, flows straight to our client’s EBITDA:

- Understanding the company’s procurement strategy: The first step we take in implementing strategic sourcing is to gain a comprehensive understanding of a client’s procurement strategy and how procurement aligns with the company’s overall business objectives. This includes identifying the goods and services that the company needs, determining the volume and frequency of purchases, and defining the criteria for supplier selection.

- Assessment of the savings opportunities: We conduct an assessment of the client’s current procurement processes to identify areas for improvement. This includes analyzing current spend data, supplier performance, and contract terms and conditions. We will also conduct cross functional team interviews, review contracts, invoices and gain an understanding of the contract management process. By the end of this step the client will have a documented understanding of their pain points.

- Planning for the sourcing process: This step starts with category management and then the team prioritizes spend categories by expected savings and difficulty of execution. We then assign categories into sourcing waves to guide the process going forward. Finally, 3-5 suppliers are identified for each category and we send RFI’s to new suppliers to help us gain a full understand their capabilities and interest.

- Issuance of a Request for Proposal (RFP): We help the client to issue a thorough RFP to the selected suppliers, outlining the specific requirements and criteria for the goods or services. The RFP includes all necessary information on the company’s needs, timelines, evaluation criteria, and other relevant details.

- Evaluation of supplier proposals: We provide criteria for us to collaboratively evaluate supplier proposals and select the suppliers that best meet the client’s needs. This includes considering factors such as price, quality, delivery times, and supplier capabilities. This also includes analyzing supplier capabilities, pricing, location, reputation, and sustainability practices.

- Negotiation and finalization of contracts: We will support negotiations with the selected suppliers to finalize the terms of the agreement. This includes pricing, delivery schedules, quality standards, and the client’s relevant terms and conditions.

- Implementation of supplier performance management: Once contracts are signed, we will help develop and implement a supplier performance management system to monitor supplier performance and ensure that they meet the agreed-upon terms and standards.

- Continuous monitoring and improvement of the procurement process: Lastly, we provide the tools for our client to continuously monitor and improve the procurement process to ensure that it remains effective and efficient. This includes measuring performance metrics, identifying areas for improvement, and implementing process improvements where necessary.

It is also important to note here that in addition to a systematic and data-driven approach to ensure that you select the best suppliers for your needs, implementing strategic sourcing also requires close collaboration between procurement, finance, and other departments to ensure that the procurement strategy aligns with the company’s overall business objectives.

Becoming a Best-in-Class Purchasing Organization

Strategic sourcing is an important step in the evolution of becoming a best-in-class purchasing organization. Other characteristics that these best-in-class organizations share include:

- Strategic Alignment: A best-in-class purchasing organization is aligned with the overall business strategy and is focused on driving value for the organization. Purchasing is seen as a strategic function that can contribute to the bottom line.

- Cross-Functional Collaboration: A best-in-class purchasing organization works closely with other functions within the organization, such as finance, operations, and supply chain, to achieve common goals and drive performance.

- Supplier Management: A best-in-class purchasing organization has strong supplier relationships and manages them strategically to drive value and innovation. This includes collaborating with suppliers on product and service design, managing performance, and optimizing costs.

- Procurement Process Optimization: A best-in-class purchasing organization has optimized its procurement processes to ensure efficiency and effectiveness. This includes leveraging technology to automate processes, standardizing processes, and reducing cycle times.

- Risk Management: A best-in-class purchasing organization has robust risk management processes in place to identify, assess, and mitigate risks related to suppliers, materials, and processes.

- Sustainability: A best-in-class purchasing organization is committed to sustainability and takes a proactive approach to managing environmental, social, and governance (ESG) risks in its supply chain.

- Continuous Improvement: A best-in-class purchasing organization is committed to continuous improvement and is constantly seeking ways to improve its performance and drive value for the business. This includes benchmarking against industry peers, implementing best practices, and investing in training and development for purchasing staff.

Best-in-class purchasing organization are dedicated to driving strategic value, collaborating effectively with other functions and suppliers, managing risk, optimizing processes, and continuously improving performance. At Hilco Performance Solutions, these are among the many areas where we our team engages with middle market manufacturing and other procurement/purchasing clients on a regular basis. We encourage you to reach out to our team to discuss your situation. We are here to help.

Hilco Performance Solutions helps companies simplify and streamline business processes, and improve operational efficiency to stay competitive and gain market share in an increasingly interconnected economy. Advisory areas of focus include Operations, Supply Chain, People, Mergers & Acquisitions and Commercial to help clients achieve sustainable revenue growth and cost reduction. While many management consulting companies focus on strategy and sharing leading theory, the Hilco team focuses on action, working in the trenches with our clients and translating strategy into actual results.