Navigating the Roadblocks: Challenges and Progress in the U.S. Electric Vehicle Revolution

The global push for sustainable transportation has marked a significant shift toward embracing electric vehicles (EVs) as a pivotal solution in combatting climate change. In the United States, the government’s influence in creating a greener future is prominent, but the journey toward widespread EV adoption continues with many challenges, particularly regarding infrastructure and technological limitations.

The U.S. Environmental Protection Agency (EPA) proposed new emissions standards in May of this year that would effectively require that 67.5% of U.S. vehicles sold to be EVs by 2032. This new proposal outstrips the Administration’s 2021 executive order of 50% EV sales by 2030 and represents an ambitious path the government is taking towards a cleaner transportation solution. However, the move towards faster EV adoption presents many challenges, especially considering that last year, EV sales accounted for only 5.8% of new light-duty vehicle sales. Consumers are not buying EVs due to a myriad of factors, from accessibility to charging stations, battery range, pricing, and cost of ownership.

Perhaps the most visible obstacle to faster adoption of EVs is the significant disparity in the charging infrastructure in distinct parts of the country. It is estimated that by 2030, 1.2 million public chargers and twenty million private chargers will be needed to meet the growing need for EVs, about 20 times the number of chargers today. Limited charging sites, coupled with long charging times ranging from 8 to 30 hours at most public chargers, create barriers to market entry that must be urgently addressed to facilitate mass adoption. It is much easier to locate charging stations in urban areas than in rural areas, and portions of the country that have sub-zero winter temperatures will struggle to attract EV buyers due to technology limitations at lower temperatures. Apartment dwellers in colder climates may well be the last to purchase an EV, due to the inconvenience of longer charging times, especially during the winter, and the need to share chargers, if they exist, with other neighboring apartment dwellers. The ability to establish a comprehensive and efficient charging network by 2032 will be key to EV adoption on a mass scale.

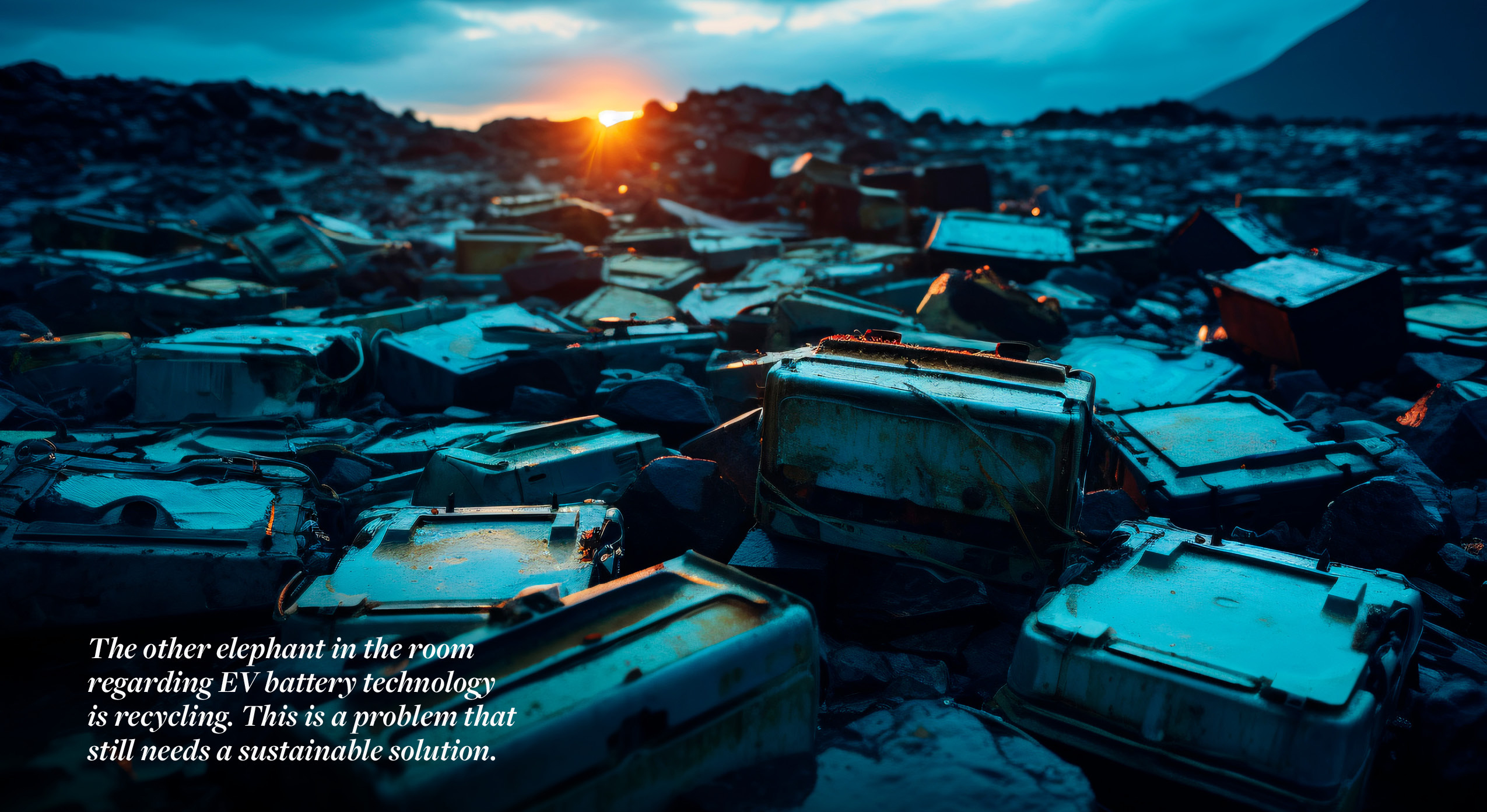

In addition to issues with charging, another barrier to entry for those looking to buy EVs is range, or mileage per charge. The highest range reported today of any EV is around 500 miles on one charge, but the average hovers around 300. EVs currently run on lithium-ion or lithium-ion phosphate battery technology. These batteries rely on a liquid electrolyte. As a liquid, these electrolytes are temperature sensitive and hold less energy due to lower energy density. Lower energy stored equals less range. Several alternative battery solutions are being developed, most notably solid-state batteries. Solid-state batteries use a solid electrolyte that performs well in both high and low temperatures, and they have higher energy densities. This technology translates into more miles per charge and faster charging times. Toyota has been working on solid-state battery technology for several years and recently published a launch timeline of solid-state batteries with varying performance levels (range/charging time) with an estimated target date of 2028. But the company has been slow on new EV vehicle development, so incorporating the new batteries into products that will be available to consumers by 2028 will be a steep order. Altruistic sharing of the patented solid-state technology with other manufacturers that do have EV product plans in the works remains to be seen. The other elephant in the room regarding EV battery technology is recycling. This is a problem that still needs a sustainable solution. The current process involves grinding up batteries to extract raw materials. This is a tedious and expensive process that also drives up the cost of ownership of EVs. Additionally, the raw materials needed for battery production are finite, and mining of these materials is often done in remote locations with little environmental oversight. As an example, China is leading the charge in nickel mining on the ocean floor, a process that is raising environmental concerns.

As expected, dealerships are at the forefront of the transformation towards EV technology and will play a crucial role in advancing this transportation transformation. To compete in the EV market, dealerships will be required to make substantial investments in electric vehicle infrastructure and technician training. While this level of investment is expensive for dealerships, it is not out of reach. It will be much more difficult for independent aftermarket service providers to make similar investments so they can continue to compete with dealers for repair business. The current US model of vehicle warranties and servicing requires a shift to aftermarket service providers once the warranty expires on a new vehicle. The American consumer relies on the lower labor and parts cost of small repair shops as well as the convenience of quick service. If the cost of entry into the EV repair space proves prohibitive for small repair shops, the number of dealership service points will have to increase substantially to handle the volume of vehicle repairs that are currently done outside of dealer networks. Failure to create this infrastructure will increase repair times, causing disruptions in an economy that depends on modes of personal transportation to operate. The move to a market filled with mostly EVs will turn the current vehicle service model upside down and further increase the cost of ownership for consumers. For Americans that already struggle to pay for repairs on older vehicles, this may put EV ownership out of reach for many and further hinder the 2032 goal of mass adoption of EV technology.

Another key facet of vehicle manufacturing is parts supply. The U.S. parts manufacturing supply base is not currently prepared to support high volumes of EV sales in the market. Parts supply for both assembly plants and aftermarket repair shops will be impacted by the rapid adoption of EVs. The accelerated push toward rapid EV adoption may solidify the role of Chinese suppliers in the U.S. market, and further complicate the ability of U.S. vehicle manufacturers to establish supply chains independent of China. Additionally, higher foreign content in EVs could consequently limit the number of EV models sold that qualify for the full $7,500 EV tax credit, further impacting affordability and the rate of EV adoption.

The mandate for electric vehicles in the U.S. is a bold step toward a more sustainable transportation system. However, the uncertainty surrounding the technology needed to move EVs forward is causing investors to wait and see what the future holds before jumping in to invest. This is a future that is hard to predict. Without significant investment in innovations in the EV space, governmental incentives and mandates will have little effect on moving the EV needle. The upcoming 2024 Presidential election is another wildcard. It is impossible to know how or if the election results will affect EV implementation. In the meantime, U.S. vehicle manufacturers have no choice but to march toward the EV goals that have been set by the government. Failure to do is to admit defeat and step out of the ring. The U.S. economy will suffer if the pace of EV implementation lags and non-U.S. manufacturers and part suppliers take over the market. We need to reach common ground quickly where the regulatory EV timeline, the pace of technological advancements, and the enormous work needed on infrastructure are understood and embraced.